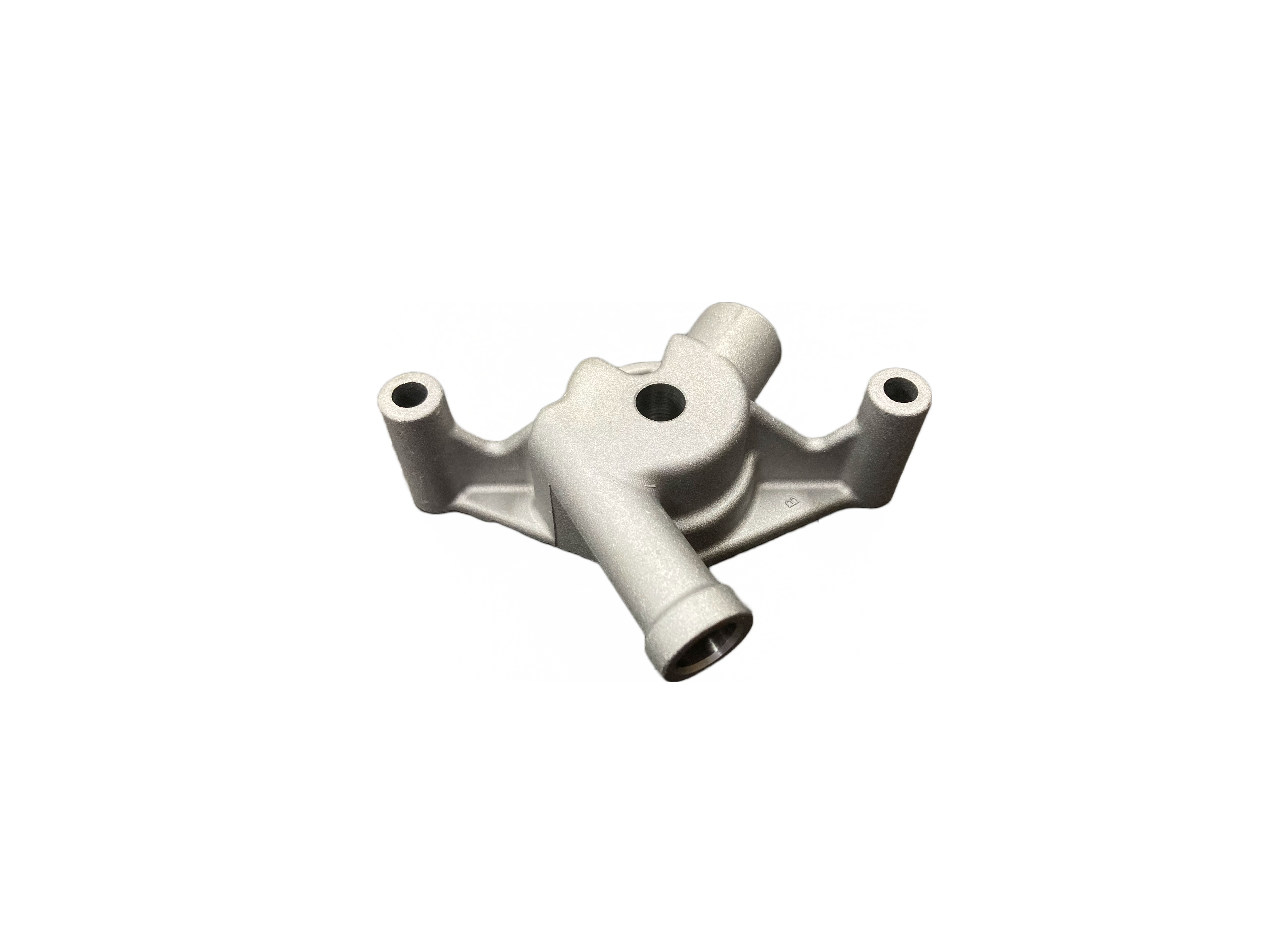

Drawing and casting plan evaluation

After the customer provides the 2D and 3D drawings of the product, it can assist in the valuation and preliminary evaluation of the die-casting feasibility, and provide advice on casting plan planning

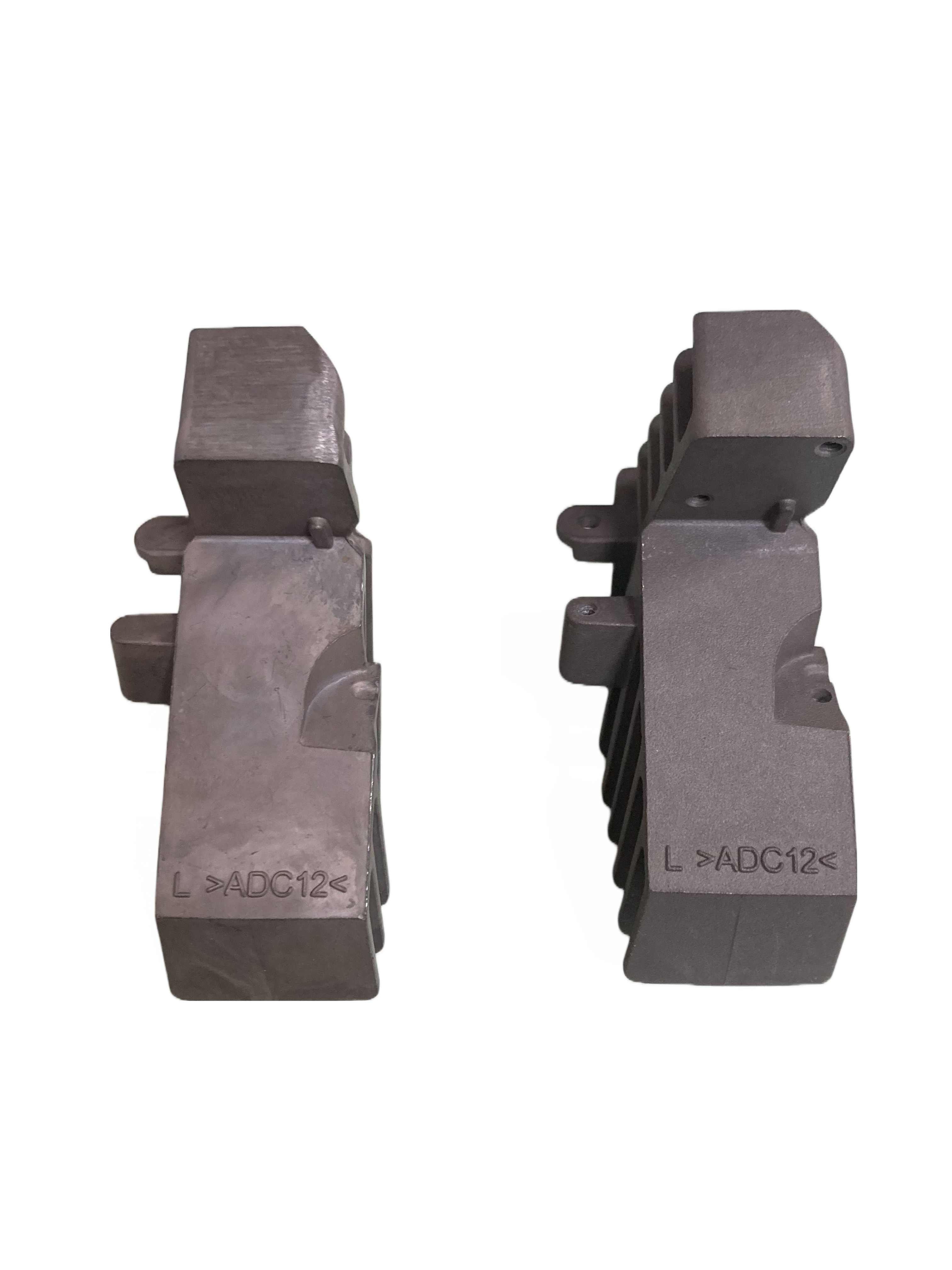

Aluminum alloy mold development

Design and develop based on experience and matching mold flow analysis software. After the plan is confirmed with the customer, the contract is issued for mold production, and the mold test and sample delivery are confirmed in the factory.

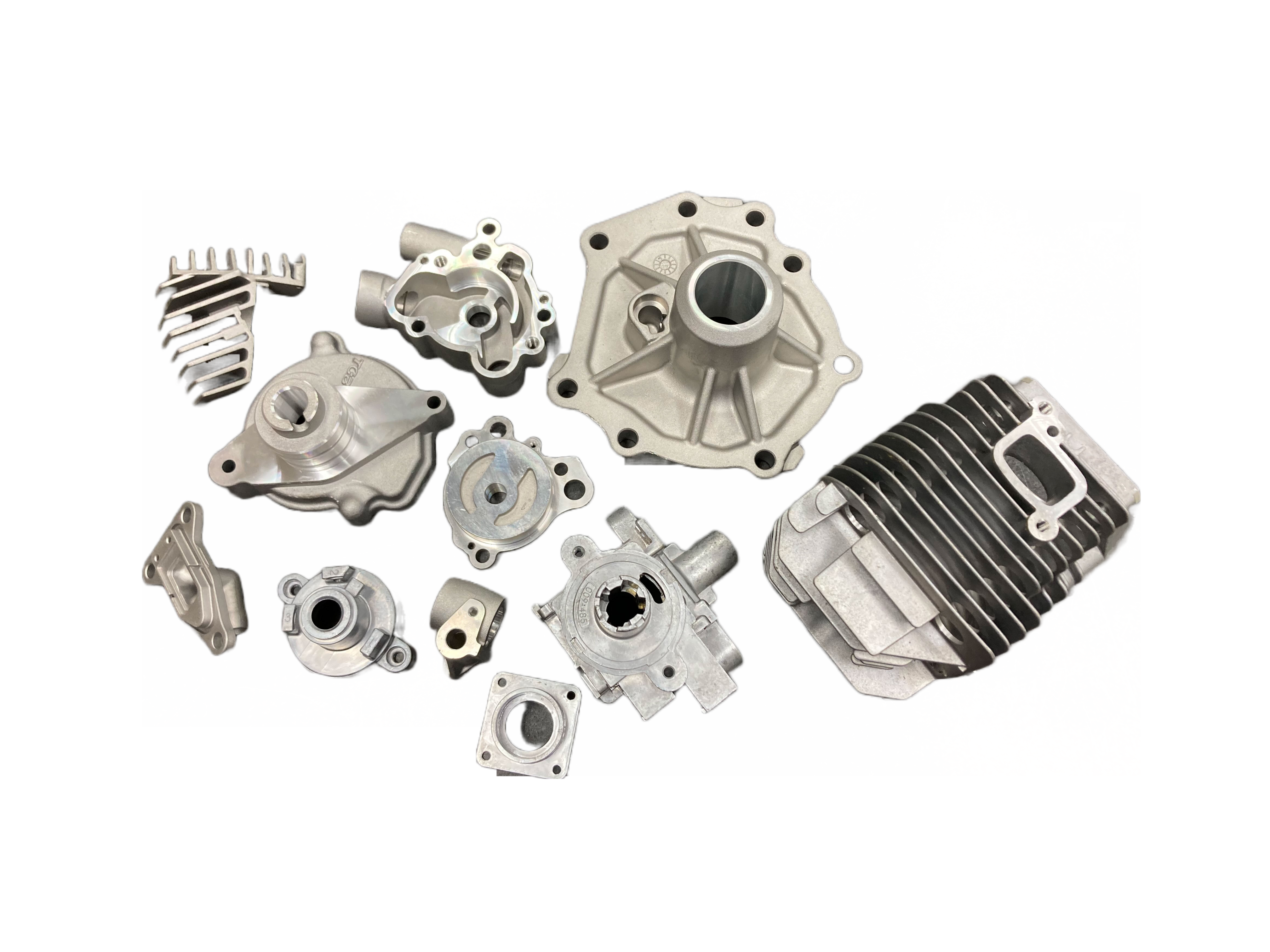

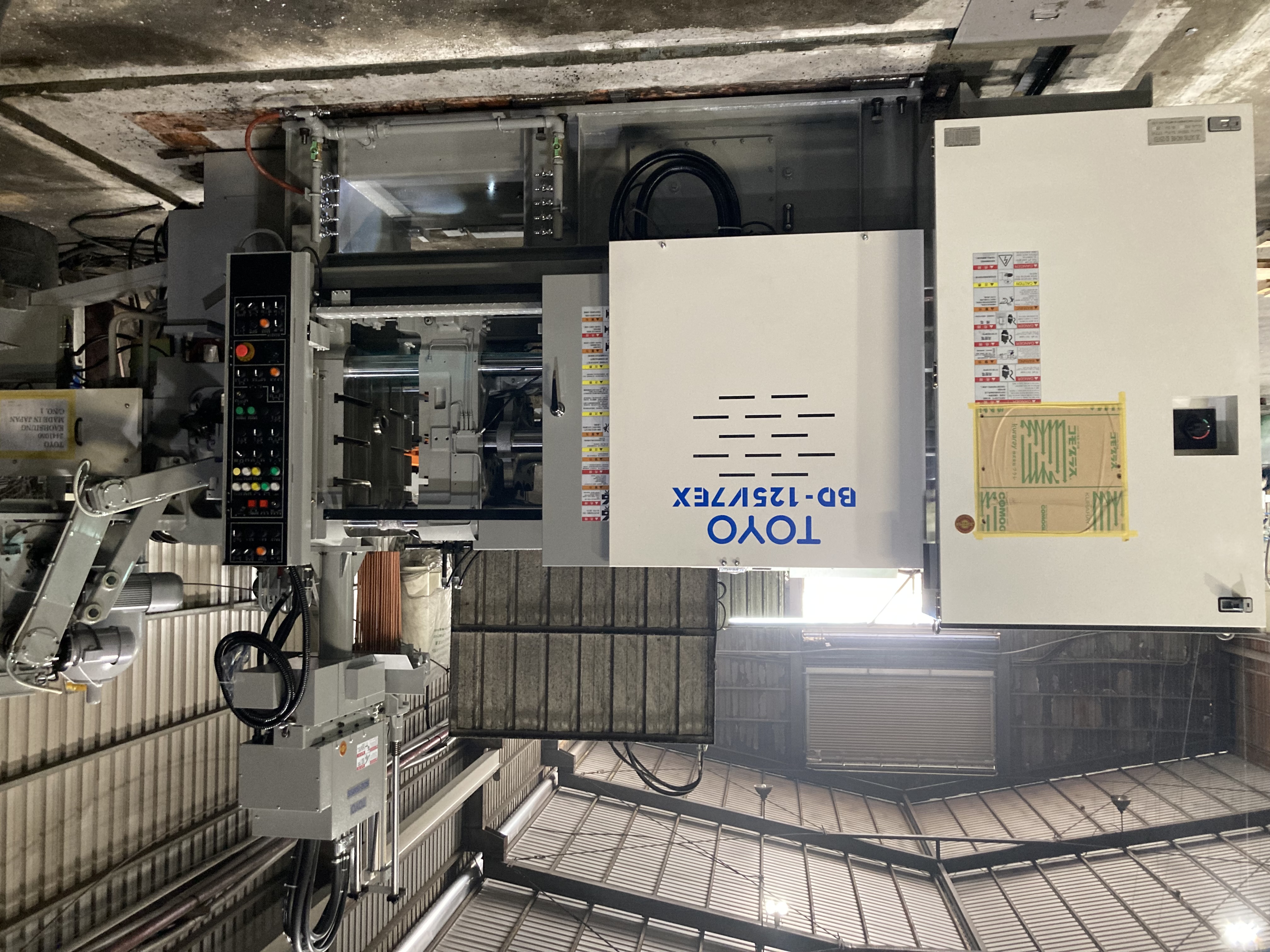

Die casting manufacturing

A total of 10 die-casting equipment from 125T to 420T can provide services, two of which are equipped with robotic arms and automatic stamping equipment

Part deburring and post-processing

After degating and deburring by hand, use a grinding or punching machine, and outsource CNC processing according to product requirements

Surface treatment

Provide different surface treatments such as sandblasting, vibrating grinding, Trivalent chromium for passivation, Anodizing, electrodeposition, baking varnish, etc.

Packing and shipping